Polyester Geogrids for Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Geogrid Introduction

Polyester Geogrid are used in base reinforcement applications such as roads and parking lots. Biaxial geogrids provide good tensile strength in both principle directions. Biaxial geogrids primary functions: reinforcement. Secondary functions: none. Lianyi has many different styles of biaxial geogrids available

Polyester Geogrid Features :

1. Pavement subgrade stabilization

2. Area /Ground stabilization

3. Pavement base reinforcement

4. Working & load transfer platforms

5. Rail Track-bed stabilization

6. Reinforced granular foundation beds

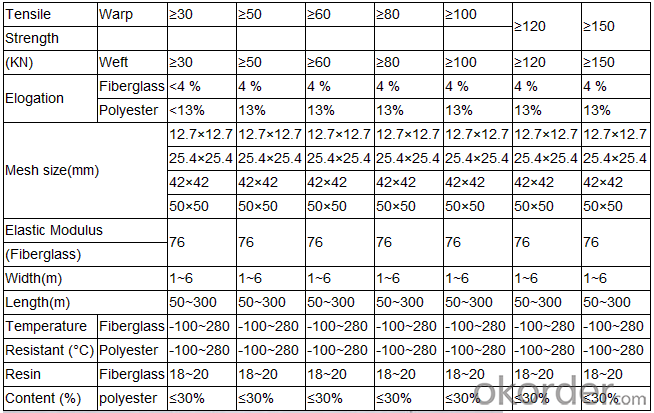

Polyester Geogrid Specification:

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q:What are the advantages of using geogrids in ground reinforcement?

- Geogrids offer several advantages in ground reinforcement. Firstly, they provide increased stability and support to the soil by distributing loads more evenly. This helps prevent soil erosion, subsidence, and deformation, making them ideal for areas with weak or unstable soils. Secondly, geogrids enhance the load-bearing capacity of the ground, allowing for the construction of structures and infrastructure on softer or less stable ground. Additionally, they improve drainage and reduce the risk of water accumulation, which can weaken the soil. Lastly, geogrids are cost-effective and environmentally friendly, as they require less excavation and use of natural resources compared to traditional ground reinforcement methods.

- Q:Are geogrids suitable for use in expansive soil conditions?

- Yes, geogrids are suitable for use in expansive soil conditions. Geogrids are commonly used in such conditions to improve the stability and strength of the soil. They help control soil movement, reduce cracking, and prevent damage to structures caused by expansive soils. Geogrids provide reinforcement and help distribute loads more evenly, making them an effective solution in expansive soil conditions.

- Q:Can geogrids be used in reinforcement of soil-lime mixtures?

- Yes, geogrids can be used in the reinforcement of soil-lime mixtures. Geogrids are commonly used to enhance the engineering properties of soil and improve its stability. When incorporated into soil-lime mixtures, geogrids can provide additional tensile strength and help distribute load more evenly, resulting in increased reinforcement and improved performance of the mixture.

- Q:Which instrument is used to measure the permeability of geotextiles?

- Is made of filament or staple through the equipment and technology of different laying into the mesh, after acupuncture process for different fiber intertwined intertwined fixing fabric specification, make the fabric soft, plump, thick, stiff, to achieve different thickness to meet the requirement of use

- Q:Can geogrids be used in reinforcement of tunnels and underground excavations?

- Yes, geogrids can be used in the reinforcement of tunnels and underground excavations. Geogrids are commonly utilized in such applications to enhance soil stabilization, reduce soil movement, and provide structural support. They can effectively distribute the load and improve the overall stability and longevity of tunnels and underground excavations.

- Q:What are the factors to consider in selecting a geogrid for a specific application?

- When selecting a geogrid for a specific application, there are several factors to consider. These include the type of soil and its properties, the expected loads and stresses on the geogrid, the desired design life and durability, the installation and construction methods, and any specific requirements or regulations for the project. Additionally, the cost and availability of the geogrid, as well as the supplier's reputation and technical support, should also be taken into account.

- Q:How do geogrids improve the performance of geotextile-reinforced retaining walls?

- Geogrids improve the performance of geotextile-reinforced retaining walls by providing additional tensile strength and stability. They work by distributing the applied loads more evenly throughout the wall, reducing the risk of wall failure due to excessive stress concentrations. Geogrids also enhance soil reinforcement, preventing soil erosion and maintaining the integrity of the wall structure over time.

- Q:How do geogrids enhance the performance of geocomposite drainage systems?

- Geogrids enhance the performance of geocomposite drainage systems by providing structural reinforcement and stabilization. They help distribute loads and prevent soil movement, improving the overall integrity and longevity of the system. Additionally, geogrids allow for better water flow and drainage, reducing the risk of water accumulation and soil saturation. This combination of increased stability and improved drainage capabilities significantly enhances the overall performance of geocomposite drainage systems.

- Q:How is the installation of geogrids carried out?

- The installation of geogrids is typically carried out by first preparing the subgrade, which involves clearing the area of any debris and ensuring a stable foundation. Then, the geogrid material is rolled out and placed on top of the subgrade. It is important to align the geogrid properly and ensure that it is not wrinkled or damaged during installation. Anchoring devices, such as spikes or staples, are then used to secure the geogrid to the subgrade. Finally, the geogrid is covered with the desired fill material, such as soil or aggregate, to complete the installation process.

- Q:What is the 110 type bidirectional geogrid?

- 110 type two-way geogrid refers to the geogrid in the horizontal and vertical direction of two can withstand the tensile strength of geogrid 110KN

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyester Geogrids for Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords