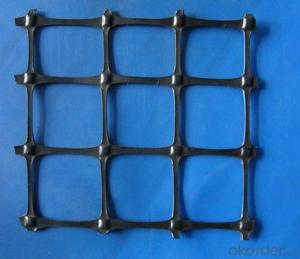

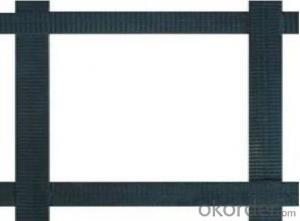

Geogrid Asphalt Reinforcement

Geogrid Asphalt Reinforcement Related Searches

Diamond Grinding Wheels For Steel Led For Cannabis Growing Plasticiser For Concrete Kst Values For Common Dusts Steel Concrete Molds Diamond Steel Roofing Stainless Steel Hole Saw Stainless Steel Sawzall Blade Cost Of Diamond Plate Aluminum 1/4 Inch Diamond Plate AluminumHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleGeogrid Asphalt Reinforcement Supplier & Manufacturer from China

Okorder.com is a professional Geogrid Asphalt Reinforcement supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geogrid Asphalt Reinforcement firm in China.Hot Products

FAQ

- Geogrids improve the performance of geocell-reinforced slopes for erosion control by providing additional strength and stability. They help distribute the load evenly across the slope, preventing soil movement and reducing erosion. Additionally, geogrids increase the frictional resistance between soil layers, enhancing the overall slope stability and preventing soil slippage.

- Yes, geogrids can be used in temporary erosion control applications. They are often used to stabilize and reinforce soil in areas prone to erosion, such as construction sites or temporary access roads. Geogrids provide strength and stability to the soil, preventing erosion and promoting vegetation growth.

- Geogrids improve the performance of geotextile erosion control blankets by providing additional stability and reinforcement. They prevent soil movement and erosion by distributing and transferring loads more effectively, enhancing the overall strength and durability of the erosion control system.

- What is the meaning of reinforced subgrade? Is there a geogrid type on the road?

- Reinforced embankment subgrade usually with earthwork material, application is very flexible, such as mesh woven with the willow branches can also do the laying of reinforcement materials in the soil, reinforced net can also, but each has advantages and disadvantages, according to the actual needs of the design.

- Yes, geogrids can be used in mining tailings containment. Geogrids are commonly used in mining operations to reinforce and stabilize various types of soil and rock structures, including tailings containment facilities. By providing tensile strength and stability, geogrids can enhance the overall integrity and performance of tailings containment systems, helping to prevent erosion, slope failure, and environmental contamination.

- How many steel wire two-way steel plastic geogrid tensile strength reached 100kn/m

- It depends on the number of steel wires, and the number of wires, and then the,

- The recommended geogrid connection method for specific applications depends on several factors such as the type of geogrid, soil conditions, and project requirements. Some common geogrid connection methods include using mechanical connectors, overlapping and sewing the geogrid panels, or using adhesive bonding. It is important to consult with a geotechnical engineer or follow the manufacturer's guidelines to determine the most suitable connection method for a specific application.