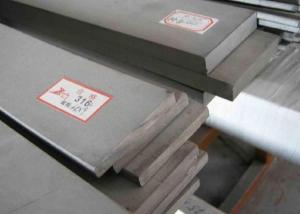

Stainless Steel Flats 316L

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q:What is the difference between 2205 and 316 stainless steel pipes?

- The chemical composition and resulting properties of 2205 and 316 stainless steel pipes differ significantly. Firstly, 2205 is a duplex stainless steel that combines austenitic and ferritic stainless steels. This unique composition grants it exceptional corrosion resistance, high strength, and weldability. It is specifically engineered to endure highly corrosive surroundings, thus making it suitable for applications in the oil and gas industry, chemical processing, and marine environments. In contrast, 316 stainless steel is an austenitic stainless steel with a higher proportion of chromium and nickel compared to 2205. Consequently, it possesses superior corrosion resistance, particularly against chlorides and other aggressive chemicals. It also exhibits commendable heat resistance and is widely employed in industries such as food processing, pharmaceuticals, and medical equipment. Regarding mechanical properties, 2205 stainless steel generally boasts greater tensile and yield strength than 316 stainless steel. This renders it more appropriate for applications where strength and durability are critical factors. However, 316 stainless steel offers better formability and is easier to work with during fabrication. In conclusion, while both 2205 and 316 stainless steel pipes provide corrosion resistance, the choice between them depends on the specific requirements of the application. 2205 is preferred for highly corrosive environments and applications necessitating high strength, whereas 316 is commonly utilized in industries where superior corrosion resistance and good formability are pivotal.

- Q:Are stainless steel pipes suitable for power generation facilities?

- Yes, stainless steel pipes are suitable for power generation facilities. Stainless steel is a highly durable and corrosion-resistant material, making it ideal for use in power generation facilities where there may be exposure to high temperatures, pressure, and corrosive environments. Stainless steel pipes can withstand the harsh conditions found in power plants, such as those used in thermal, nuclear, and renewable energy generation. Additionally, stainless steel has excellent heat resistance properties, making it suitable for transporting hot gases or fluids within power generation systems. The ability of stainless steel pipes to resist corrosion and maintain their structural integrity over time ensures the reliability and longevity of power generation facilities.

- Q:Classification, advantages and disadvantages of stainless steel welding

- Metal gas shielded arc welding.It belongs to the gas protection welding, also is a kind of arc welding, that is, in the protection of gas, welding rod arc melting. Metal gas welding can be used in steel, non alloy steel, low-alloy steel and high alloy, etc. these materials are widely used. But one thing, its protective gas must be an active gas, such as carbon dioxide or a mixture of gases. The only drawback is that if the outdoor welding, then the workpiece can not be damp, otherwise it will affect the protection of gas protection effect.

- Q:Can stainless steel pipes be used for sewage and wastewater systems?

- Indeed, sewage and wastewater systems can make use of stainless steel pipes. Stainless steel is renowned for its exceptional resistance to corrosion, rendering it highly suitable for water and sewage-related purposes. Its ability to withstand rust, corrosion, and chemical reactions ensures an extended lifespan while reducing the necessity for frequent replacements. Moreover, stainless steel pipes possess a smooth surface that hinders the accumulation of debris and facilitates effortless cleaning. Furthermore, stainless steel is impermeable, preventing the growth of harmful bacteria and fungi, thus contributing to its hygienic nature and suitability for sewage and wastewater systems. The durability, dependability, and capacity to withstand harsh environmental conditions make stainless steel pipes a favored choice for such applications.

- Q:Are stainless steel pipes suitable for power generation plants?

- Yes, stainless steel pipes are highly suitable for power generation plants. They possess excellent corrosion resistance, high strength, and durability, making them ideal for handling high-pressure and high-temperature fluids and gases found in power generation processes. Stainless steel pipes also offer exceptional resistance to various chemicals, ensuring the integrity and longevity of the piping system in power plants. Additionally, their smooth inner surface minimizes frictional losses, enhancing the efficiency of fluid transportation within the plant.

- Q:Are stainless steel pipes suitable for geothermal applications?

- Indeed, geothermal applications can benefit greatly from the use of stainless steel pipes. Geothermal systems rely on harnessing the earth's natural geothermal energy, which often necessitates the conveyance of hot fluids like water or steam. When it comes to this purpose, stainless steel pipes are an ideal selection due to their exceptional strength, resistance to corrosion, and ability to endure high temperatures. They possess the capability to withstand the demanding conditions typically found in geothermal environments, including the presence of acidic or corrosive fluids, while exhibiting a lower likelihood of degradation over time compared to other materials. Furthermore, stainless steel pipes boast excellent thermal conductivity, thereby ensuring the efficient transfer of heat in geothermal applications. All in all, one can confidently consider stainless steel pipes as a dependable and long-lasting choice for geothermal systems.

- Q:Can stainless steel pipes be powder coated?

- Yes, stainless steel pipes can be powder coated. Powder coating is a durable and protective finish that can be applied to stainless steel pipes to enhance their appearance and provide additional corrosion resistance.

- Q:Are stainless steel pipes suitable for high-temperature steam?

- Yes, stainless steel pipes are suitable for high-temperature steam. Stainless steel is known for its excellent heat and corrosion resistance, making it an ideal material for applications involving high temperatures and steam. The high chromium and nickel content in stainless steel helps it withstand the corrosive effects of steam, preventing oxidation and maintaining its structural integrity. Additionally, stainless steel pipes have high strength and durability, ensuring they can handle the pressure and stress caused by high-temperature steam. Overall, stainless steel pipes offer a reliable and long-lasting solution for transporting high-temperature steam in various industries such as power generation, chemical processing, and oil and gas.

- Q:What is the maximum temperature limit for stainless steel pipes?

- The maximum temperature limit for stainless steel pipes depends on the specific grade of stainless steel used. Generally, stainless steel pipes can withstand high temperatures ranging from 1200°F (650°C) to 1600°F (870°C). However, it is crucial to consider the specific alloy composition, as some grades of stainless steel have higher temperature resistance than others. Additionally, factors such as the duration of exposure to high temperatures and the presence of corrosive substances can also affect the maximum temperature limit. Therefore, it is essential to consult the manufacturer's specifications or seek professional advice to determine the exact maximum temperature limit for a specific stainless steel pipe application.

- Q:What are the factors to consider when selecting stainless steel pipes for a specific application?

- When selecting stainless steel pipes for a specific application, several factors need to be considered to ensure the right choice is made. 1. Corrosion Resistance: Stainless steel is known for its exceptional resistance to corrosion, but different grades offer varying levels of protection against specific corrosive environments. The type of corrosive agents present in the application, such as chemicals, moisture, or high temperatures, should be carefully evaluated to select a stainless steel grade that can withstand them effectively. 2. Temperature and Pressure: Stainless steel pipes are used in a wide range of temperature and pressure conditions. The selected grade must have the necessary strength and resistance to handle the specific temperature and pressure levels required by the application. Higher temperatures may require grades with increased heat resistance, while high-pressure environments may benefit from pipes with higher tensile strength. 3. Material Compatibility: In some applications, stainless steel pipes may come into contact with other materials or substances, such as liquids or gases. It is crucial to consider the compatibility of the stainless steel with these materials to avoid any potential chemical reactions, contamination, or degradation. Compatibility testing or consulting with experts can help determine the best choice of material. 4. Size and Dimensions: The size and dimensions of the stainless steel pipes should match the requirements of the application. This includes considering the diameter, thickness, and length of the pipes. Proper sizing ensures optimal flow rates, structural integrity, and ease of installation. 5. Cost: Cost is always a factor to consider in any decision-making process. Different stainless steel grades vary in price, and it is essential to balance the desired properties with the available budget. While cost should not be the sole determining factor, it is important to find a stainless steel pipe that meets the required specifications without exceeding the allotted budget. 6. Standards and Certifications: Depending on the application, certain standards and certifications may be required, such as ASTM, ASME, or ISO. These standards ensure that the stainless steel pipes meet specific quality and performance criteria. It is crucial to select pipes that comply with the necessary standards and have appropriate certifications to ensure reliability and safety. 7. Maintenance and Durability: Consider the maintenance requirements and expected lifespan of the stainless steel pipes. Some applications may require regular cleaning, inspection, or maintenance, while others may need pipes with long-term durability and resistance to wear and tear. By carefully evaluating these factors, one can make an informed decision when selecting stainless steel pipes for a specific application, ensuring they meet the necessary performance, quality, and safety requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Flats 316L

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords