Steel Prop & Tripod for build formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

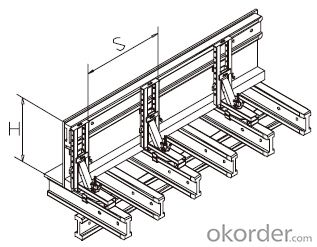

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q:How do steel props compare to wooden shores in terms of durability?

- Steel props are generally more durable than wooden shores. Steel props are made from a sturdy and resilient material, making them less susceptible to damage from compression and wear over time. On the other hand, wooden shores are more prone to rot, decay, and splitting, which can significantly affect their durability. Overall, steel props provide better longevity and can withstand harsher conditions, making them a preferred choice when it comes to durability.

- Q:What is the maximum spacing between steel props?

- Various factors, such as the load capacity of the props, the dimensions of the structure, and the project requirements, influence the maximum spacing between steel props. However, engineering calculations and recommendations from the manufacturer or industry standards generally determine this spacing. The purpose of steel props is to offer temporary support during construction or renovation, guaranteeing the stability and integrity of the structure. Thus, it is crucial to appropriately space the props, ensuring effective load distribution and preventing any potential structural failures or collapses. Engineers consider the load weight and distribution, material properties, structure dimensions, prop type, and any supplementary support or reinforcement measures when determining the maximum spacing between steel props. To determine the maximum spacing for a specific project, it is vital to consult with a qualified structural engineer or adhere to the manufacturer's guidelines. This ensures the safety and stability of the supported structure.

- Q:In the construction of the cast-in-place floor of the fastener type steel pipe support system, which belongs to the full scaffold, or belong to the template and support system

- Formwork and support system.Full scaffolding is generally used for single storey workshop, hall and other floors, the construction of the ceiling of a large architectural decoration. By the vertical rod, bar, diagonal bracing, scissors, etc..

- Q:What are the disadvantages of using steel props?

- Using steel props in construction projects comes with a few drawbacks. Firstly, the weight and size of steel props can make transportation and handling on-site quite challenging. This can result in increased labor costs and time spent setting up and dismantling the props. Secondly, steel props may have limited adjustability. Although they can be extended or shortened to some extent, they may not be as flexible as other support systems. This can be problematic for projects that require precise adjustments or in areas with uneven ground. Another disadvantage is the potential for corrosion. Steel props are prone to rust and deterioration when exposed to moisture or harsh environmental conditions. This can shorten their lifespan and necessitate regular maintenance or replacement, which adds to the overall project expenses. Furthermore, steel props can cause noise and vibrations during construction activities. This can be bothersome for nearby residents or workers and may require additional measures to minimize these disturbances. Lastly, steel props tend to be more expensive compared to other temporary support systems. Depending on the project requirements and duration, alternative options such as timber or aluminum props may offer a more cost-effective solution. In conclusion, although steel props have their advantages in terms of strength and load-bearing capacity, it is crucial to consider these disadvantages when selecting the appropriate support system for a construction project.

- Q:How do steel props compare to screw jacks in terms of stability?

- During construction activities, temporary support can be provided by using steel props or screw jacks. When it comes to stability, both steel props and screw jacks have their own advantages and limitations. Steel props, which are also referred to as adjustable props or acrow props, are typically constructed using steel tubes with a threaded end and a removable pin. Their main purpose is to support vertical loads and provide stability to structures during construction. The robust construction of steel props allows them to offer excellent stability and withstand heavy loads. They are especially suitable for supporting larger structures or heavy loads, as their load-bearing capacity is higher compared to screw jacks. On the other hand, screw jacks consist of a threaded rod and a large plate that rests on the ground or a suitable base. They are commonly used for leveling or supporting smaller structures. The height of the rod can be adjusted in order to provide stability and precise leveling or support. While screw jacks are generally stable, their load-bearing capacity is lower compared to steel props. They are typically used for lighter loads or situations where precise adjustments are required. To summarize, both steel props and screw jacks offer stability, but their suitability depends on the specific requirements of the construction project. Steel props are more appropriate for supporting larger structures or heavier loads, while screw jacks are often used for smaller structures or situations that require precise adjustments. When choosing between steel props and screw jacks, it is important to consider the load requirements, the size of the structure, and the desired level of stability.

- Q:Can steel props be used in seismic zones?

- Steel props can be used in seismic zones, but their use should be carefully evaluated and designed to ensure they can withstand the potential seismic forces. Steel props are commonly used in construction to support temporary structures or to provide additional support to existing structures during renovation or repair work. In seismic zones, where there is a higher risk of earthquakes, it is essential to consider the specific requirements and regulations related to seismic design. These requirements typically include factors such as the expected level of ground shaking, the building's location, the structural system, and the type of material used. Steel props can be designed to withstand seismic forces by considering factors such as their size, shape, material strength, and connection details. The design should take into account the expected seismic loads and incorporate appropriate safety factors to ensure the props can resist these forces without failure. In addition to proper design, it is also crucial to ensure that the installation and anchorage of steel props in seismic zones are carried out correctly. This may involve using specific techniques or additional reinforcement measures to enhance their stability and resistance to seismic forces. Ultimately, the use of steel props in seismic zones is possible, but it requires careful evaluation, design, and installation to ensure their effectiveness and safety. Consulting with structural engineers and adhering to local building codes and regulations is crucial to ensure that steel props are appropriately used in seismic-prone areas.

- Q:How do you prevent damage to adjacent structures when using steel props?

- When using steel props, there are several measures that can be taken to prevent damage to adjacent structures. 1. Conduct a thorough survey and assessment: Before using steel props, it is essential to conduct a detailed survey of the surrounding area. This should include identifying any adjacent structures, utilities, or sensitive areas that may be at risk of damage. Assess the condition of these structures and determine their load-bearing capacity. 2. Ensure proper installation and positioning: Steel props should be installed and positioned correctly to provide adequate support. This involves following the manufacturer's instructions and guidelines, ensuring that the props are securely fastened and properly aligned. It is crucial to check for any obstructions or uneven surfaces that may affect the stability of the props. 3. Use appropriate load-bearing capacity: Make sure to select steel props with the appropriate load-bearing capacity for the specific application. Overloading the props can lead to structural failure and potential damage to adjacent structures. Consult with structural engineers or experts if necessary to determine the correct load-bearing capacity required. 4. Monitor and inspect regularly: Regular monitoring and inspection of the steel props during the construction process are essential. This includes checking for any signs of movement, deformation, or stress on the props or adjacent structures. Any abnormalities should be addressed immediately to prevent further damage. 5. Implement protective measures: Depending on the situation, additional protective measures may be necessary to prevent damage to adjacent structures. This can include using structural shoring, bracing, or strengthening techniques to distribute the loads more evenly and minimize any potential impact on surrounding structures. 6. Communication and coordination: Open communication and coordination with the project team, including adjacent property owners, is crucial. Informing them about the construction activities, potential risks, and mitigation measures will help minimize any potential damage and ensure everyone is prepared and aware of the situation. Ultimately, preventing damage to adjacent structures when using steel props requires careful planning, proper installation, regular monitoring, and the implementation of protective measures. Following these steps will help maintain the safety and integrity of both the construction site and the surrounding structures.

- Q:Can steel props be used to support walls during demolition?

- Yes, steel props can be used to support walls during demolition. Steel props, also known as adjustable steel acrow props, are commonly used in construction and demolition projects to provide temporary support to walls, ceilings, and other structures. They are designed to withstand heavy loads and can be adjusted to the desired height and length to provide stability and prevent collapsing during demolition. Steel props are especially useful when demolishing load-bearing walls, as they can effectively distribute the weight and ensure the safety of the surrounding structures. Additionally, steel props are easy to install and remove, making them a versatile and cost-effective solution for supporting walls during demolition.

- Q:Are steel props suitable for use in high-voltage transmission line construction?

- High-voltage transmission line construction does not lend itself well to the use of steel props. These props, typically employed in construction activities for temporary structural support, are not ideal in this particular context for several reasons. First and foremost, high-voltage transmission lines carry extremely powerful electrical currents. Given steel's conductivity, using steel props in close proximity to these lines would heighten the risk of electrical accidents. Should the props come into contact with the transmission lines, they could conduct electricity, posing a significant danger to workers and potentially causing damage to equipment. Secondly, steel props may lack the necessary insulation properties required for high-voltage environments. High-voltage transmission lines often operate at voltages ranging from 69,000 volts to over 500,000 volts. It is imperative to ensure that any equipment employed in their construction is adequately insulated so as to prevent the occurrence of electrical discharge or arcing between the props and the transmission lines. Moreover, steel props may not possess the structural strength and stability necessary for high-voltage transmission line construction. These lines frequently span lengthy distances and endure various environmental factors such as wind, ice, and temperature fluctuations. The props employed in their construction must be capable of withstanding these forces and maintaining stability, which may not be guaranteed with steel props. Instead, specialized equipment and tools specifically designed for high-voltage transmission line construction are utilized. These include insulated aerial lifts, conductive ropes, and other safety gear engineered to meet the unique requirements and safety standards associated with working near high-voltage infrastructure. In conclusion, due to their conductive nature, lack of insulation properties, and potential structural limitations, steel props are unsuitable for high-voltage transmission line construction. Prioritizing safety and utilizing specialized equipment tailored to working in high-voltage environments is of utmost importance in order to minimize risks and ensure the successful completion of these projects.

- Q:Can steel props be used in the construction of temporary educational or classroom facilities?

- Yes, steel props can be used in the construction of temporary educational or classroom facilities. Steel props, also known as adjustable steel props or acrow props, are support structures commonly used in construction projects to provide temporary support to walls, ceilings, or other structures during construction or renovation. Temporary educational or classroom facilities often require quick and easy installation, as well as the ability to be relocated or dismantled easily. Steel props are ideal for this purpose as they are lightweight, versatile, and can be adjusted to various heights, making them suitable for different types of structures and layouts. Additionally, steel props are durable and stable, providing a secure and safe support system for temporary educational or classroom facilities. They are designed to withstand heavy loads and are made of high-quality steel, ensuring their structural integrity and reliability. Moreover, steel props are cost-effective compared to other support systems. They can be rented or purchased at a reasonable price, making them a cost-efficient option for temporary construction projects like educational or classroom facilities. In conclusion, steel props can indeed be used in the construction of temporary educational or classroom facilities due to their versatility, durability, and cost-effectiveness.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Prop & Tripod for build formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords