Tripod & Beam Clamp formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Steel Prop & Tripod & Beam Clamp

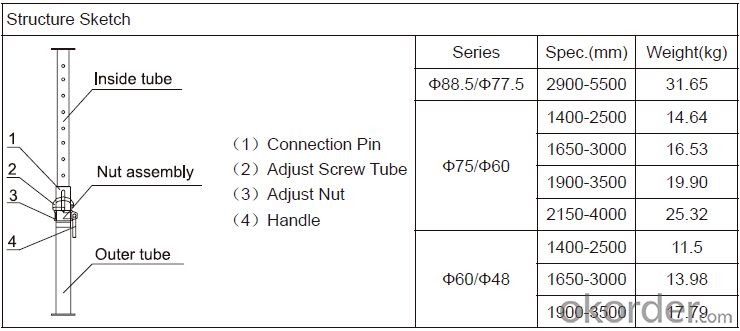

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

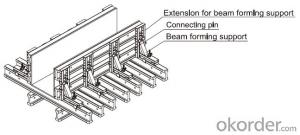

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q:What are the advantages of using steel props over traditional wooden supports?

- There are several advantages of using steel props over traditional wooden supports. Firstly, steel props offer greater strength and durability compared to wooden supports, making them more reliable and long-lasting. Secondly, steel props are adjustable, allowing for easy customization and adaptability to different heights and load-bearing requirements. Additionally, steel props are non-combustible, providing enhanced safety in situations where fire hazards are a concern. Lastly, steel props are lightweight and easy to handle, simplifying the transportation and installation process.

- Q:In the tunnel construction, with steel arch, steel grille, steel support, which is what mean? What is the use of high reward?!

- Steel grille is a arch, the main difference is the steel grid by rebar welding assembly, looks like a cage, commonly known as flower arch

- Q:What is the typical warranty period for steel props?

- The typical warranty period for steel props can vary, but it is generally around 1 to 5 years, depending on the manufacturer and the specific product.

- Q:Can steel props be used for temporary support in bridge pier construction?

- Steel props are a viable option for providing temporary support in the construction of bridge piers. They are frequently employed in construction endeavors to offer temporary support to structures throughout the construction process. These props can be easily adjusted and provide a dependable and robust support system. When it comes to bridge pier construction, steel props can bear the weight of the pier and guarantee its stability until permanent supports, like concrete piers or abutments, are established. Steel props possess versatility, as they can be adjusted to various heights and angles, making them suitable for a variety of bridge pier construction scenarios. Nonetheless, it is crucial to ensure that the design, installation, and monitoring of the steel props are done properly to ensure the safety and stability of the bridge pier during construction.

- Q:Do steel props require regular maintenance?

- Yes, steel props do require regular maintenance. Regular inspections should be conducted to check for any signs of damage or wear, and any necessary repairs or replacements should be made promptly. Additionally, proper cleaning and lubrication should be carried out to ensure optimal performance and longevity of the steel props.

- Q:How do steel props compare to hydraulic jacks in terms of performance?

- Construction projects commonly utilize steel props and hydraulic jacks to support heavy loads or provide temporary structural support. Despite serving similar purposes, there are significant performance differences between the two. Steel props, also called adjustable steel props or acrow props, consist of telescopic tubular steel columns with adjustable lengths. They are primarily employed to support formwork, beams, slabs, or other construction elements. Known for their high load-bearing capacity and stability, steel props are ideal for heavy-duty applications. They offer ease of installation and adjustment, allowing for flexibility in various construction scenarios. Furthermore, steel props are cost-effective and durable, ensuring long-term support. Conversely, hydraulic jacks utilize hydraulic fluid to exert force and lift or support heavy loads. These versatile tools find application in a wide range of contexts, including lifting vehicles or machinery, supporting structures during repairs, and even within the automotive industry. With precise control over the lifting process and significant lifting capacity, hydraulic jacks outperform steel props in certain aspects. They are generally more compact and portable, facilitating easy transportation and setup. When assessing performance, it is crucial to consider the specific project requirements. Steel props excel in providing robust and stable support for vertical loads, making them suitable for demanding construction tasks. They prove particularly valuable in scenarios where a high load-bearing capacity is necessary, such as supporting concrete slabs or beams. Additionally, steel props offer straightforward adjustment to accommodate different heights or angles. On the other hand, hydraulic jacks exhibit greater versatility and agility in lifting or supporting loads. They prove especially useful when precise control over the lifting process is vital, such as when dealing with heavy machinery or vehicles. Hydraulic jacks enable incremental adjustments and can be operated remotely or with specialized equipment, ensuring convenience and safety during lifting operations. To summarize, steel props and hydraulic jacks possess distinct strengths and are suited for different applications. Steel props excel in providing heavy-duty vertical support, while hydraulic jacks offer versatility and precise control in lifting operations. The choice between the two depends on the specific project requirements, required load capacity, and desired level of control and convenience.

- Q:Can steel props be used for supporting temporary outdoor stages or performance venues?

- Steel props are a viable option for supporting temporary outdoor stages or performance venues. They are widely utilized in the construction industry and offer robust and secure support for various structures. These props are engineered to withstand substantial loads and can be adjusted to achieve desired heights and angles. Employing steel props for temporary outdoor stages or performance venues can enhance the safety and stability of the structure, especially in regions with unpredictable weather conditions or uneven terrain. Furthermore, steel props possess versatility and can be effortlessly installed and dismantled, making them ideal for temporary setups. Nevertheless, it is imperative to seek guidance from a structural engineer or a professional in the field to ensure the appropriate selection and utilization of steel props based on the specific requirements of the stage or venue.

- Q:How do you prevent unauthorized access to steel props on construction sites?

- To ensure the safety of workers and maintain the project's integrity, it is crucial to prevent unauthorized access to steel props on construction sites. Here are several steps that can be taken to achieve this: 1. Establish a secure perimeter: Utilize fences and barriers to create a secure boundary around the construction site. Clearly mark restricted areas with signs indicating the prohibition of unauthorized entry. 2. Implement access control measures: Enforce strict access control by using controlled entry points and identification systems. This can involve the use of access cards, biometric scanners, or security personnel to regulate entry to the site. 3. Install surveillance systems: Strategically place CCTV cameras throughout the construction site to monitor and record activities, particularly in areas where steel props are stored or used. Maintain and regularly check the functioning of the surveillance system. 4. Ensure adequate lighting: Install lighting systems that illuminate all areas of the construction site, especially those where steel props are stored. Sufficient lighting can make it more difficult for unauthorized individuals to enter unnoticed. 5. Secure storage areas: Use robust locking mechanisms, such as padlocks or combination locks, to secure areas where steel props are stored. Regularly inspect and replace locks if needed. 6. Employ security personnel: Assign trained security personnel to patrol the construction site and monitor access points. They should be prepared to respond promptly and effectively to any unauthorized access attempts. 7. Conduct regular inventory checks: Regularly inspect steel props to ensure they have not been tampered with or stolen. Maintain a record of all props and their locations to quickly identify any discrepancies. 8. Provide employee training: Educate all construction site workers on the significance of preventing unauthorized access to steel props. Foster a culture of security and vigilance among the workforce. 9. Install alarm systems: Set up alarms that can be triggered by unauthorized entry attempts. These alarms should be loud and easily audible to alert security personnel or nearby workers. 10. Regularly inspect the site: Conduct routine inspections of the construction site to identify any vulnerabilities or weaknesses in the security measures. Continuously improve security protocols based on these inspections. By implementing these preventive measures, construction site managers can greatly reduce the risk of unauthorized access to steel props, ensuring the safety of workers and the successful completion of the project.

- Q:What are the main differences between adjustable and non-adjustable steel props?

- The main differences between adjustable and non-adjustable steel props lie in their functionality and versatility. Adjustable steel props allow for height adjustment, making them suitable for various construction projects where the height of the supported structure may need to be altered. On the other hand, non-adjustable steel props have a fixed height and are typically used in situations where the height requirement remains constant throughout the project. Additionally, adjustable steel props offer increased flexibility and adaptability, as they can be easily extended or reduced in height, while non-adjustable props are more rigid and limited in their applications.

- Q:Can steel props be used in the installation of temporary signage or banners?

- Yes, steel props can be used in the installation of temporary signage or banners. Steel props are commonly used as supports for various structures, including temporary ones like signage or banners. They provide stability and strength, ensuring that the signage or banner is securely in place. Steel props can be easily adjusted to the desired height and are resistant to weather conditions, making them suitable for outdoor installations. Additionally, steel props can be reusable, making them a cost-effective option for temporary signage or banners.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tripod & Beam Clamp formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches