Steel Prop & Tripod for Build

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

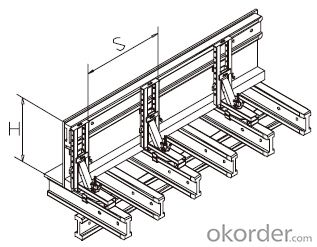

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q:Can steel props be used for supporting temporary bridges during emergencies?

- Indeed, steel props have the capability to support temporary bridges in emergency scenarios. Their robustness and longevity make them an ideal option for offering provisional assistance to bridges during critical situations. They possess the ability to effectively bear the bridge's weight and guarantee its stability until a permanent resolution can be implemented. Furthermore, steel props are adjustable, facilitating effortless installation and customization to meet the specific demands of the bridge. Moreover, steel props are readily accessible and extensively utilized in construction, rendering them a pragmatic selection for emergency bridge support.

- Q:Can steel props be used for temporary support in oil and gas projects?

- Temporary support in oil and gas projects can be achieved using steel props. These props are commonly utilized in construction, maintenance, and repair activities across various industries, including the oil and gas sector. They are adjustable in height and can be effortlessly installed and removed, making them well-suited for temporary support purposes. In oil and gas projects, steel props play a vital role in supporting heavy machinery, equipment, pipelines, and other infrastructure during construction, installation, or maintenance tasks. They guarantee the stability and safety of the structures, effectively preventing any potential collapse or damage. Furthermore, steel props are renowned for their ability to bear heavy loads, durability, and resistance to harsh environmental conditions, all of which are crucial factors in the demanding oil and gas industry. They can withstand the considerable loads and challenging operating conditions typically encountered in these projects. Moreover, steel props offer the advantage of flexibility when it comes to adjusting their height. This adaptability proves particularly beneficial in oil and gas projects, where the temporary supports may need to be repositioned or their height altered as the project progresses. Overall, steel props are a dependable and practical solution for temporary support in oil and gas projects. They provide a safe and efficient means of ensuring structural stability and can be readily utilized in various applications within the industry.

- Q:Can steel props be used for temporary support in airport construction?

- Yes, steel props can be used for temporary support in airport construction. Steel props, also known as adjustable steel props or steel acrow props, are commonly used in construction projects to provide temporary support to structures or excavations. They are adjustable in height and can be easily installed and removed, making them suitable for temporary support in various construction applications, including airport construction. Steel props are made from high-quality steel, which makes them highly durable and capable of withstanding heavy loads. They are commonly used to support formwork, scaffolding, and other temporary structures during construction. In airport construction, steel props can be used to provide support to temporary structures such as formwork for concrete works, scaffolding for maintenance or installation of equipment, or even during excavation works. The adjustable height feature of steel props allows for flexibility in supporting different heights and requirements in airport construction. They can be extended or retracted to reach the desired height, and their load-bearing capacity can be adjusted accordingly. This flexibility makes them an ideal choice for supporting temporary structures in airport construction, as the needs and requirements of the project can vary depending on the specific stage of construction. Furthermore, steel props are easy to install and remove, which saves time and labor during airport construction. They can be quickly assembled and dismantled, allowing for efficient use of resources and reducing construction timelines. This is particularly important in airport construction, where time is often a critical factor. Overall, steel props are a reliable and versatile solution for providing temporary support in airport construction. Their durability, load-bearing capacity, adjustability, and ease of installation make them suitable for a wide range of applications, ensuring the safety and efficiency of the construction process.

- Q:What safety precautions should be taken when using steel props?

- When using steel props, it is important to take several safety precautions. First, ensure that the props are properly inspected for any signs of damage or wear before use. Additionally, the props should be set on a level and stable surface to prevent any accidents. It is crucial to follow the manufacturer's guidelines regarding weight limits and proper positioning of the props. Lastly, always use the appropriate personal protective equipment, such as gloves and safety goggles, to avoid any potential injuries while handling or adjusting the steel props.

- Q:Are steel props resistant to vibration or impact?

- Steel props possess exceptional strength and durability, rendering them remarkably resilient against vibration and impact. With their solid design, these props proficiently absorb and disperse vibrations, guaranteeing steadfastness and diminishing the likelihood of harm stemming from external forces. Moreover, their sturdy composition enables them to endure impacts without substantial distortion or structural breakdown. Consequently, steel props prove to be an outstanding option for endeavors necessitating paramount vibration or impact resistance, including construction, scaffolding, and temporary support systems.

- Q:Can steel props be reused?

- Yes, steel props can be reused. Steel props are adjustable metal support devices commonly used in construction projects to provide temporary support to structures during construction or renovation work. They are designed to be durable and reliable, and with proper maintenance, they can be reused multiple times. After completing a construction project, the steel props can be dismantled, inspected, and if found to be in good condition, they can be cleaned, repaired if necessary, and stored for future use. Reusing steel props not only helps reduce waste and save money but also ensures that construction projects can be completed efficiently and safely. However, it is important to note that proper inspection and maintenance are crucial to ensure the structural integrity and safety of the steel props before reusing them.

- Q:Can steel props be used in telecommunications tower construction?

- Certainly! Steel props have the capability to be utilized in the construction of telecommunications towers. Commonly referred to as temporary support systems or scaffolding, steel props are frequently employed in construction projects to offer structural support and stability. Throughout the construction process, they can provide support for various components of a telecommunications tower, including the mast, antennas, and equipment platforms. Constructed from high-strength steel, steel props possess the ability to be adjusted in height, thereby allowing for flexibility in tower construction. These props are specifically designed to endure heavy loads and deliver stability to the structure. Moreover, steel props are easily installed, dismantled, and repositioned, rendering them an appropriate choice for the dynamic nature of telecommunications tower construction.

- Q:How is the load capacity of a steel prop determined?

- The load capacity of a steel prop depends on several factors that consider the properties of the material and the design specifications. Firstly, the load capacity is affected by the type and grade of steel utilized in the prop. Steel props are commonly manufactured using high-strength, low-alloy steels that can withstand heavy loads. The properties of the steel, such as its yield strength, ultimate tensile strength, and elongation, play a significant role in determining the load capacity. Additionally, the load capacity is determined by the design specifications of the prop, including its dimensions, shape, and reinforcement. The length, diameter, and wall thickness of the prop impact its ability to resist bending and compression, which directly affects the load-bearing capacity. Moreover, features like internal ribs or flanges can improve the strength and stability of the prop, thus increasing its load capacity. Furthermore, the load capacity is influenced by the distribution of the load and the method of support. Steel props are commonly employed in construction to support vertical loads, such as beams or slabs. The load capacity is calculated based on the maximum load that the prop can endure while maintaining stability and structural integrity. To determine the load capacity, engineers conduct various tests, such as compression tests, bending tests, or load deflection tests. These tests measure the performance of the steel prop under different load conditions and provide valuable data for determining the safe working load and ultimate load capacity. In conclusion, accurately determining the load capacity of a steel prop is crucial to ensure the safety and stability of the supported structure. This is achieved by considering the material properties, design specifications, and conducting performance tests.

- Q:How do you ensure proper bracing of steel props?

- Proper bracing of steel props can be ensured by following a few key steps. Firstly, it is important to accurately calculate the required number of props and their spacing based on the load-bearing capacity and the dimensions of the structure. Secondly, props should be positioned vertically and aligned properly to ensure their stability. Additionally, the use of adjustable props allows for precise adjustments and leveling. Lastly, diagonal bracing should be installed to provide lateral support and prevent any potential buckling or collapse. Regular inspections and maintenance are also crucial to identify any signs of damage or weakness and address them promptly.

- Q:How to speed up the construction speed of steel support in the excavation area

- The design of pre axial force (force along the direction of the line per meter of straight brace under the effect of the length of the steel support) multiplied by the

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Prop & Tripod for Build

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords