Hallway Ceiling Light Fixtures

Hallway Ceiling Light Fixtures Related Searches

Best Inverter For Solar System Led Light For Chandelier Decorative Ceiling Plate For Light Fixture Inverter For 5kw Solar System Parts For Light Fixtures Transformer For Light Fixture Decorative Lights For Ceiling Lights For Kitchen Ceiling Ceiling Brackets For Lights Hanging Ceiling Chairs For BedroomsHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Plate For Sale Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Aluminum Bar Stock For SaleHallway Ceiling Light Fixtures Supplier & Manufacturer from China

Okorder.com is a professional Hallway Ceiling Light Fixtures supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Hallway Ceiling Light Fixtures firm in China.Hot Products

FAQ

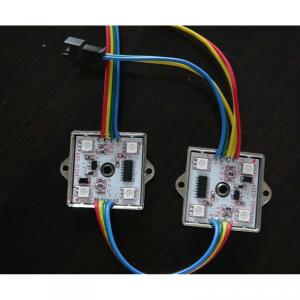

- The quality of the LED patch module

- Quality of circuit board. In the same quality of LED, the quality of PCB will have an important impact on the life of LED. The circuit board is divided into aluminum plate, glass fiber board, semi glass fiber board and paperboard. The quality of aluminum is the best, the best cooling effect, but the cost is too high, the domestic manufacturers generally only in high-power LED products use, LED module manufacturers generally use cardboard, semi glass fiber and glass fiber board. Module, piranha, straw hat module monochrome is generally used in cardboard or semi glass, commonly used glass fiber or semi SMD glass fiber board. Colorful and full color module series generally at least half of glass fiber, so as to match.

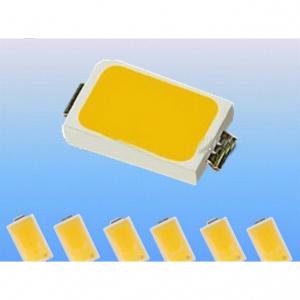

- Patch LED features

- Without heating time, lighting is faster than general light (about 3 ~ 400ns).The electro optic conversion efficiency is high, the power consumption is small, and the energy consumption is about 1/3 ~ 1/20 than that of the bulb.

- What is patch SMD-LED?

- This really do not know how to answer you, like a sheet of the same type of solder paste used to operate, it can be said that the plug-in is not, it is patch it!

- Patch LED beads can be bought in what place?

- SMD LED lamp is now very popular, mainly because of long service life, but also rarely appear dead lights or dark, but there are many defects exist

- What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- It is best to use a hot-air gun heat transfer high air volume adjustable low moment welding, the specific heat jump to the appropriate place to see what you use what kind of welding wire, welding wire of different because of the different melting point impurities also some differences. The air volume is too high, easy to blow the original

- Patch LED market conditions

- Chinese suppliers also offer mature, but less profitable two-color and trichromatic products, which are mostly used in backlighting, appliances, consumer products, consumer electronics and display. Despite low market demand, vendors continue to offer sideview SMD LED, including 335 (4008), 020 (3806) and 215 (2810)

- Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- First of all, welding LED and other electronic products with line electrostatic ring, to prevent static light.When welding the patch LED lamp, first add the tin on the pad of the lamp board, then clamp the LED patch lamp with tweezers. Then, the soldering iron will melt the tin of the solder plate of your lamp board, and then push the LED lamp onto the pad with tweezers. The whole welding process should not exceed 5 seconds, otherwise it will burn the lamp easily.

- How many volts is a single LED on the LED patch band?

- LED patch lamp is made of FPC circuit board, LED lamp and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.