Kitchen Ceiling Led Light Fixtures

Kitchen Ceiling Led Light Fixtures Related Searches

Best Inverter For Solar System Led Light For Chandelier Decorative Ceiling Plate For Light Fixture Inverter For 5kw Solar System Parts For Light Fixtures Transformer For Light Fixture Decorative Lights For Ceiling Lights For Kitchen Ceiling Ceiling Brackets For Lights Hanging Ceiling Chairs For BedroomsHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Plate For Sale Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Aluminum Bar Stock For SaleKitchen Ceiling Led Light Fixtures Supplier & Manufacturer from China

Okorder.com is a professional Kitchen Ceiling Led Light Fixtures supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Kitchen Ceiling Led Light Fixtures firm in China.Hot Products

FAQ

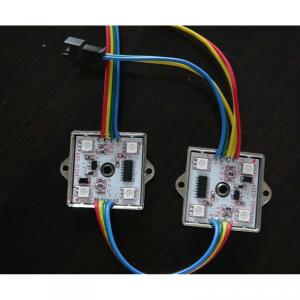

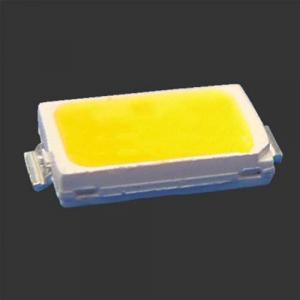

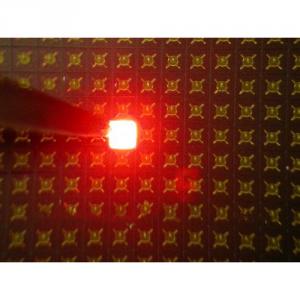

- What is patch LED?

- LED is usually the lead pins form, need to be drilled on the printed circuit board, the LED pin is inserted in the hole, welded with wave soldering machine; and the patch type LED is used in welding surface, flat welded on the circuit board.

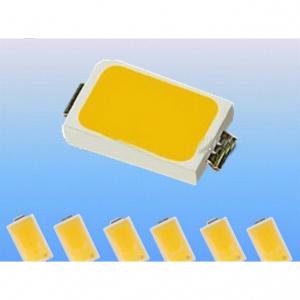

- Patch LED beads can be bought in what place?

- Many LED packaging plants do patch LED, you can find the relevant manufacturers to contact, or go to the local electronic components market according to your needs

- How to detect LED SMD beads

- The output voltage of the digital clock diode file is not high, generally below 2.5V, so the measurement of LED lamp does not work, the best way is to external electrical measurement. If there are a lot of beads to measure it, can take a constant current power measurement.

- What are the storage requirements of SMT patch LED (LED)?

- Keep in storage- the original sealing bag packing in the condition of the <40 C and <90% RH degrees for 12 months, more than the storage period will bake.Please check the leak before opening the packing bagIn opening the sealed bag, should be placed in SMD LED and C 60%RH. < < 30 degrees under the conditions in the above conditions, SMD LED must be in the open package using reflow within 24 hours. If placed more than 24 hours, you need to bake- baked, SMD LED in C + 80 degrees 5 degrees C and <=10%RH relative humidity in the oven for 24 hours? remove the pouch before baking, and do not open the oven door frequently

- Patch LED light broken one, short circuit can use it?

- Can not casually short-circuit, according to the LED connection, but also to see the power supply voltage and current, all the LED can not flow. Any short circuit may cause excess LED to flow over or over, causing a chain reaction, a bad string,...... .

- What is the difference in performance between the LED plug-in and the LED patch?

- 1, the patch is relatively easy to heat dissipation, can be directly welded on the aluminum substrate, heat faster.2, in general, there is a straw type shell, general lighting has front facing directivity, just look at it, brightness will be the biggest. The patch has a relatively wide divergence angle and is more suitable for fluorescent lamps.

- Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- The welding speed and welding time because certainly give light foot heat, so the speed must be fast, tin wire and tip with better, while heating to tin iron head, avoid heating time is too long.

- Led lamp and Led patch two what is the difference between ah, the feeling is a patch of long service life, whether or not? 5-10 meters pan area lighting lamp selection Everbright shaped or patch shape?

- If you take a large area light, to see that the lighting requirements, functional lighting, or lighting atmosphere, or ordinary lighting, which is to be considered, the two optical (lens) can bring you the light angle planning.