All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

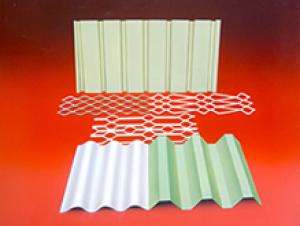

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How can aluminum profiles be adapted for high-temperature applications in the manufacturing of advanced machinery?

Aluminum profiles can be adapted for high-temperature applications in the manufacturing of advanced machinery through various methods. One approach is to select aluminum alloys with high melting points and excellent thermal stability. These alloys typically have additions of elements like magnesium, copper, or zinc, which enhance their heat resistance. Additionally, aluminum profiles can be subjected to heat treatment processes such as precipitation hardening or solution annealing to further improve their high-temperature performance. Furthermore, the use of thermal barriers or coatings can provide insulation and protect the aluminum profiles from extreme heat. Overall, careful alloy selection, heat treatment, and additional protective measures can effectively adapt aluminum profiles for high-temperature applications in advanced machinery manufacturing.

What are the considerations for using aluminum profiles in the production of energy-efficient HVAC systems?

There are several considerations for using aluminum profiles in the production of energy-efficient HVAC systems. Firstly, aluminum profiles offer excellent thermal conductivity, allowing for effective heat transfer and improved energy efficiency in HVAC systems. Additionally, aluminum profiles are lightweight yet strong, making them suitable for constructing energy-efficient systems without adding excessive weight. Moreover, aluminum is highly corrosion-resistant, ensuring the longevity and durability of HVAC systems in various environments. Lastly, aluminum profiles can be easily recycled, promoting sustainability and reducing the environmental impact of HVAC production. Overall, these factors make aluminum profiles a favorable choice for energy-efficient HVAC system production.

What is the role of aluminum profiles in the aerospace industry's weight reduction efforts?

Aluminum profiles play a crucial role in the aerospace industry's weight reduction efforts by providing a lightweight yet strong structural component. These profiles are used in various applications, such as aircraft fuselage, wings, and interior fittings, where reducing weight is essential for improving fuel efficiency and increasing payload capacity. The use of aluminum profiles allows for significant weight savings without compromising structural integrity, making them an integral part of the aerospace industry's ongoing efforts to enhance aircraft performance and reduce environmental impact.

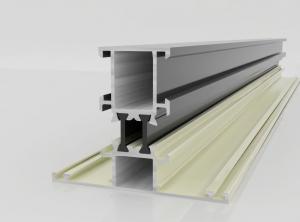

Wholesale Aluminum Profiles from supplier in Tanzania

We are a Aluminum Profiles supplier serving the Tanzania, mainly engaged in the sale, quotation, and technical support services of various Aluminum Profiles products in the Tanzania region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Aluminum Profiles procurement services in the Tanzania. Not only do we have a wide range of Aluminum Profiles products, but after years of market development in the Tanzania, we can also provide valuable experience for your projects.