Colorful decoration fiber glass wall panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Colorful decoration fiber glass wall panel

Specification:

Standard Size: 600mm*600mm, 600mm*1200mm…

Standard Thickness: 25, 30, 40, 50mm…

Edge Detail: Square, Bevel

Technical Data of Fiberglass Wall Panel:

Material: Torrefaction compounded high density fiberglass wool

Facing: wrpped with special decorative fabric

Fire-resistant: Base board: Class A, Finished board:Class B2

Humidity: Dimensionally stable with RH up to 90% at 40℃

Environmental: Tiles and packing materials are fully recyclable

Colorful decoration fiber glass wall panel

Main Characteristic of Fiberglass Ceiling:

Excellent sound absorption

No sagging, wrapping or delaminating

Fire-resistant

Moisture resistant

Excellent light reflectance

Cleanable

Environmentally friendly

Application Areas of Fiberglass Ceiling:

Commercial Halls,Classrooms,Offices,Libraries,Shopping Centers,Music Rooms,Auditoriums,etc.

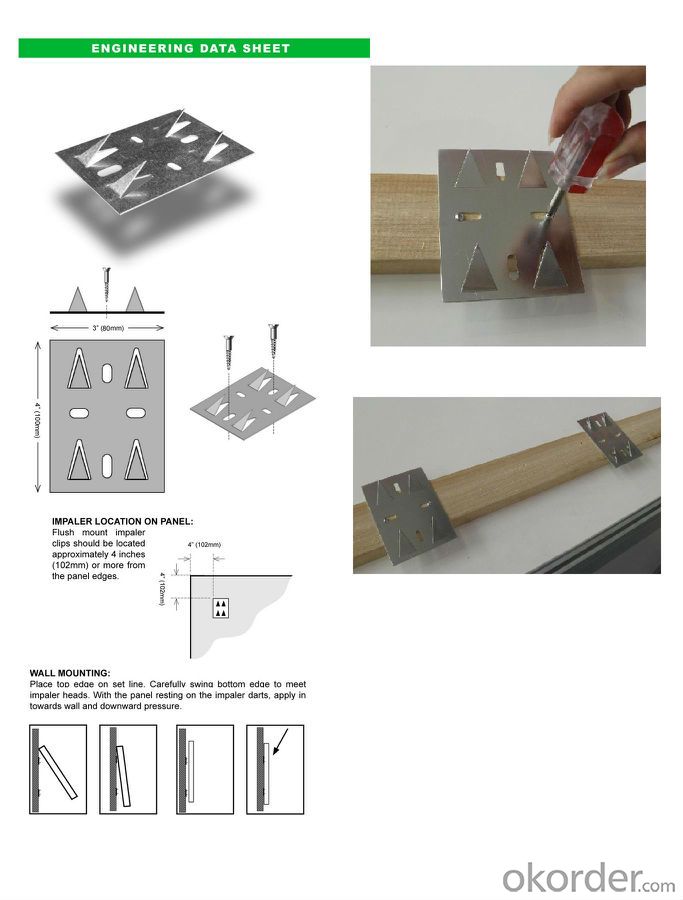

How to install:

Colorful decoration fiber glass wall panel

- Q:Glass fiber mesh quality soft and hard for the wall, which is better?

- The general wall of the grid with a fast money about 1 square meters on the good. Tengda grid cloth 8 hair can also be used. Selling is also good,

- Q:The difference between GRC lightweight partition board and ceramic plate

- Hello, the difference between the two is great GRC lightweight partition board: glass fiber reinforced cement to do the board; GRC has a thin structure, high resistance to stretch, good impact resistance, low alkalinity, free expansion rate of small crack performance and reliable, stable quality, moisture, , Non-combustible, sound insulation, can be sawed, drillable, can be nailed, can be shaved, can chisel, wall smooth construction Jane. Grc components are generally used in high-end villa exterior decoration or European-style building on the external walls of decoration. If the grc component of the type of large number of large Friends of the grc can be opened in the project next to a temporary plant to facilitate the construction of the late, grc components can be divided into color and gray.

- Q:Wall material that kind of environmental protection?

- Diatom mud soft bag wallpaper floor wall is now a lot of latex paint is also very environmentally friendly

- Q:Grc light partition board construction steps is what

- 1, the process Material inspection → technology to the end of the net → clean-up → line → fixed U-shaped steel plate card → live installation → detection of vertical, flatness → fixed GRC light partition board → repeat the vertical degree, flatness → support pipe → tied to the joints with → seam mortar → scraping putty → polished smooth → surface coating. The following are the same as the " 2, prepare materials and construction tools Before the construction, need to prepare GRC lightweight partition board materials and doors and windows supporting frame bench material, and to prepare construction tools, such as temporary fixed fixture "U" type fixture, "L" type fixture, to be horizontal angle iron Of the pry bar, woodworking board saw, putty knife, wooden wedge and so on. The following are the same as the " According to the requirements of the drawings, in the wall and the roof pop-up wall and the location of the doors and windows. And the office, corridors, halls and other rooms are ceiling, so the need for height in the partition wall to do hanging columns and hanging beams.

- Q:What is the quality of the light barrier now?

- The partition board includes glass fiber reinforced concrete slab, glass fiber reinforced gypsum hollow slab, steel wire (steel mesh) reinforced concrete slab, light concrete slab, composite sandwich light bar and so on. The full name is the building wall with a light strip, as a general industrial buildings, residential buildings, public works of non-load-bearing wall of the main material. It is a lightweight partition project which is a non-bearing internal wall of a commercial building, a residential building and a public building project with a light partition.

- Q:What is the difference between GRC reinforced concrete slabs and lightweight aggregate concrete partitions?

- GRC reinforced cement board: glass fiber reinforced cement board, glass fiber is used as a reinforcing material, plus cement, sand, water, admixture and other materials made of slats, which apply to ordinary or mid-range building grade. Glass fiber reinforced concrete (GRC-Glass Fiber Reinforced Cement) is a new type of composite material.

- Q:How to do with glass fiber wall anti-crack

- First look at what is the wall, is the load-bearing walls, non-load-bearing walls, as well as the original wall is now there are cracks? Do the best way to do anti-crack wall is to shovel the original wall shovel, a plaster leveling or low-level gypsum leveling, after drying in the use of ecological white latex patch, cloth to use really good, so you can prevent the wall The surface is cracked.

- Q:Inorganic fiberglass contrast color steel composite board which is good? Requirements insulation good! preservative! Thank you

- Fiberglass is a glass fiber reinforced plastic commonly known as it is a glass fiber reinforced material, synthetic resin as the base material of the composite products. FRP has a good anti-corrosion properties. Especially the water and dilute the concentration of acid Liquid, and can show its superiority, and FRP lightweight high strength specific gravity of 1.7-1.8 is a quarter of steel.For the insulation: you can use polyurethane foam. With light weight. High strength. Low thermal conductivity. Non-absorbent and other characteristics. Has been widely used in travel. Building. Cold storage. Refrigerator. Petrochemical. Indoor air conditioning.

- Q:What should the overall wardrobe design should have?

- The main features of the overall wardrobe are: standardized modules, tailor-made. The overall wardrobe according to the different styles can be divided into integral, into the wall, support and into the four categories. The overall design of the wardrobe and the pursuit of harmony with the home, in a warm atmosphere of life, bringing a simple and stylish charm, so that you poetic dwelling, artistic life. Therefore, the overall wardrobe style selection and design is essential:

- Q:What is GRC and can I paint it?

- GRC is the abbreviation of Glass Fiber Reinforced Cement, which is a new type of composite material invented in the 1970s. It is made of alkali-resistant glass fiber as reinforcing material, sulphoaluminate low basicity cement as cemented material and mixed with suitable aggregate Substrate, by jetting. Mold casting. Squeeze out. Flow pulp and other processes made of new inorganic composite materials. The It combines light, high strength, high toughness and water resistance, non-combustion, sound insulation, heat insulation, corrosion resistance, easy processing and other characteristics set in one, occupies a unique position in the building. In recent years, China's GRC technology to a new stage of development. The GRC technology can produce Roman column, eaves line, waist line, door cover, window cover, top set, window side column, light partition board, transformer Such as flue, railing, garden relief, Tibetan components, antique components, mountain flowers, corridor, cultural stone and other hundreds of varieties, smooth and exquisite appearance of the components, pattern smooth realistic, stereotypes perfect, strong sense of art. The following are the same as the " 2, construction, easy installation, short duration. Production of various GRC prefabricated components, with cement affinity. Nine blogs J o? ~?] 5Z?]?]? L 3, GRC components light weight, high strength, good toughness, no cracking, no layer, water, non-combustible, and housing with the life. Spray on the paint, with the stone fought. 4, no "waste" pollution, is conducive to environmental protection. 5, loss. If there is a small amount of damage in the transport can also be installed after the completion of the decoration with cement, to ensure that the utilization of components 100%.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Colorful decoration fiber glass wall panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products