Prime Quality Tinplate for MR Steel With 0.26mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prime Quality Tinplate for MR Steel With 0.26mm

1.Structure of Description

Prime Quality Tinplate for MR Steel With 0.26mmis one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

For 0.26 tinplate sheet, there are many customers used for produce food cans or edibil oil cans, if you have some same request, pls contact.

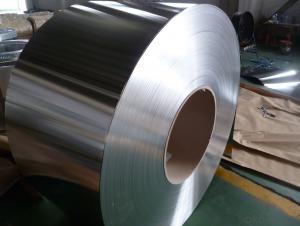

3. Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.31

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

D. Can it make to be BA or CA for annealing?

Yes, both can do with.

- Q:Tin can bake oven electrical electromagnetic induction principle

- If it is not sealed, it is said to be heated and then changed after being heated.

- Q:How does tinplate perform in terms of odor and taste retention?

- Tinplate is known for its excellent odor and taste retention properties. It forms a protective barrier that prevents any transfer of odors and flavors between the packaging material and the contents. This makes tinplate a preferred choice for packaging sensitive food and beverage products, ensuring that their quality and taste remain intact.

- Q:How is tinplate stored and handled?

- Tinplate is typically stored in a dry and well-ventilated area to prevent rusting. It should be kept away from moisture, chemicals, and direct sunlight. When handling tinplate, it is important to use proper lifting equipment to prevent damage and injuries. It should be stored in a way that avoids excessive stacking and ensures easy access for inspection and use. Proper labeling and documentation of storage is also recommended to ensure efficient handling and inventory management.

- Q:Can tinplate be used for aerospace applications?

- Yes, tinplate can be used for certain aerospace applications, particularly for non-critical components where weight is not a significant concern. Tinplate is known for its corrosion resistance and affordability, which makes it suitable for certain aerospace applications such as interior fittings, non-structural parts, and packaging. However, for critical components that require high strength-to-weight ratio or extreme durability, other materials like aluminum or titanium are typically preferred.

- Q:The difference between a matte tin plate and a bright tin plate

- Silver tinplate:Silver surface processing refers to the original plate in plating passivation treatment after reflow treatment and the surface has a unique stable luster; after printing and coating, the operation of creating a gorgeous and elegant atmosphere, used in the manufacture of advanced art cans, nuts, etc..

- Q:What are the cleaning agents suitable for tinplate?

- Some cleaning agents suitable for tinplate include mild dish soap, vinegar, and baking soda. It is important to avoid abrasive cleaners or harsh chemicals that can damage the tinplate's surface.

- Q:What are the main advantages of using tinplate for electrical enclosures?

- The main advantages of using tinplate for electrical enclosures include its high strength and durability, excellent corrosion resistance, and good electrical conductivity. Tinplate is also lightweight and easy to form, making it a cost-effective choice for manufacturing enclosures. Additionally, tinplate is recyclable, making it an environmentally friendly option for electrical applications.

- Q:How does tinplate affect the overall product freshness?

- Tinplate plays a significant role in preserving the overall product freshness. Its unique properties, such as excellent barrier properties against light, oxygen, and moisture, help in extending the shelf life of the contents inside the tinplate packaging. This prevents oxidation, spoilage, and contamination, ensuring that the product remains fresh and retains its quality for a longer period of time.

- Q:What are the main applications of tinplate in the cosmetics industry?

- Tinplate is extensively used in the cosmetics industry for packaging purposes. It is commonly employed for manufacturing containers such as cans, jars, and tubes for various cosmetic products like creams, powders, lip balms, and hair care products. Tinplate provides excellent protection against moisture, light, and other external factors, ensuring the longevity and quality of the cosmetic products. Additionally, its malleability allows for intricate designs and attractive branding possibilities, making it a popular choice in the cosmetics industry.

- Q:How does tinplate perform in high-temperature applications?

- Tinplate generally performs well in high-temperature applications due to its high melting point and excellent heat resistance properties. It can withstand temperatures up to 250 degrees Celsius without significant deformation or loss of its protective tin coating. However, at temperatures above this range, tinplate may start to experience oxidative reactions and potential degradation. Additionally, prolonged exposure to high temperatures can cause the tin coating to become brittle and lose its protective properties. Therefore, while tinplate is suitable for many high-temperature applications, it is important to consider specific temperature limits and potential impacts on its performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime Quality Tinplate for MR Steel With 0.26mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords