Customized AL 65 Aluminum Formwork for Concrete Wall Formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of AL 65 Aluminum Formwork

The whole system is made from aluminum materials. As the picture shown, every formwork unit is formed by CNBM production line. There are three special customized section bars form our standardization manufacture, and every formwork unit is welded by Robot.

AL 65 is a complete system with a full set of accessories, and can be set up flexibly according to project.

2. Main Features of AL 65 Aluminum Formwork

1.Lighter weight but high bearing capacity.

The allowable pressure from fresh concrete is 60KN/m2 with the thickness of 65mm.

2.Manual transportation can be achieved, greatly reduces the aggregate cost.

3. Perfect design, excellent produce and well welding make sure the flatness of concrete surface.

4.It is with the advantages of standard design, excellent applicability and interchangeable.

5.Simple, safe and fast.

6.No rust corrosion, easy maintenance, and high turnover rate.

3. AL 65 Aluminum Formwork Images

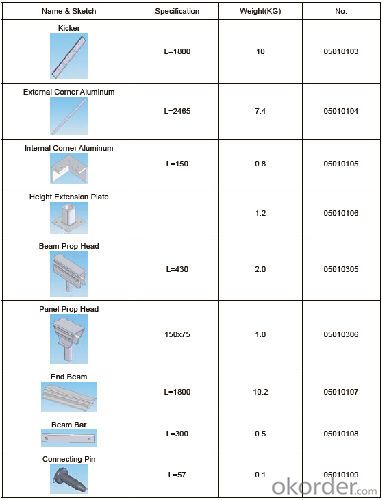

4. AL 65 Aluminum Formwork Specification

5. FAQ of AL 65 Aluminum Formwork

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in AL 65 Aluminum Formwork, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of AL 65 Aluminum Formwork, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:How to do the foundation beam template

- The main body of each layer of concrete using fixed pump delivery. Before pouring, it is necessary to clear the debris in the template and advance the wet mode, the concrete vibration needs to be timely, coherent, and shall not leak slurry, reinforcement intensive place need to strengthen the vibration, to ensure the concrete density. Concrete vibrator should try to avoid the direct vibration of the template, to prevent the expansion of the joints at the seams, so as to set up the site to inspect the quality of the template.Wall column concrete pouring in place, to prevent the beam, the plate when pouring overflow phenomenon affect the appearance quality, the wall column concrete pouring should be carried out in time for two times to ensure that the structure section size is correct, the founder does not distort deformation.

- Q:I would like to ask the template support system Liang Xiaoliang Ban Xiaoliang refers to what

- High formwork concrete beams are usually large in size, gravity load, plan people sometimes use 50 x 100 (width * height) wood brace, called Liang Xiaoliang, a thin concrete slab gravity load is less, with 30 * 80 mu Fang, challenge the small beam. According to the different rib beam floor plan, good people, they try to use the same specifications of the wooden architrave, there is no Liang Xiaoliang, small plate beam, just calculate book Liang Xiaoliang, trabecular plate.

- Q:The main floor beam template installation should pay attention to what?

- Install the bottom die, the beam according to the span length of 3 m to the bottom of the beam arch, to ensure that after the completion of concrete pouring, floor thickness and deflection to meet the requirements of the drawings. Beam from the end of the 500mm, in the bottom of the beam to keep a clean mouth, to be cleaned up debris, it will be blocked. The side beam mould die bag bottom mold method, and clip stickers in the template angle at.

- Q:The calculation of formwork engineering quantity of ground beam needs to calculate the bottom of beam

- The calculation of the formwork quantity of the beam is not needed to calculate the bottom of the beam

- Q:When the main beam and secondary beam connection, calculate the area of the template is good, there is no simple method

- It would take the high beam length reduced thickness, and by 2, the last plus beam bottom

- Q:10-3 degrees of weather, cast in situ floor and girder formwork can be demolished a few days? 25 days enough? There's a wall on the beam.

- When the bottom formwork of the reinforced concrete slab with a span of 5m is removed, the concrete strength should be greater than or equal to 75% of the standard value of concrete cube compressive strength.

- Q:Remove the larger span of the beam pillar template why should be removed from the middle to the two ends

- The maximum bending moment in the middle of the beam is removed from the middle of the support, the stress is concentrated on the two supporting end, and the final force form is the same as the reinforcement of the beam, and the bending and the excessive shear force are not generated

- Q:What is the demolition order of the construction template

- 1 demolition vertical face template, should be carried out from top to bottom; demolition of the larger span of the beam pillar, should start from the middle, respectively, to the two ends.2 demolition of beams and floor bottom mold, should loosen the wedge or lower bracket, then by block or patch removal

- Q:Should not be on the front and back of the four sides of the template? Why is the width of the beam length multiplied by the beam surface? Isn't that the three face?

- Only the surface and the side surface of the template, when pouring the concrete pouring can together from above.

- Q:Beam column plate template how to calculate the need to deduct what part?

- The second is to calculate the template of the beam to calculate the template of the beam with the section length multiplied by the length of the unit is M2Finally the board notice when calculate the template template amount is peripheral template must take and post together part to deduct the intersection with beam part to be deducted

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Customized AL 65 Aluminum Formwork for Concrete Wall Formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords